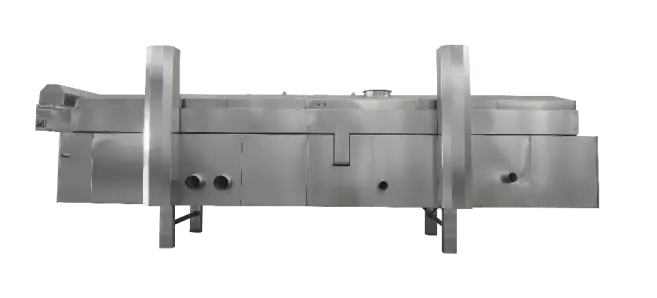

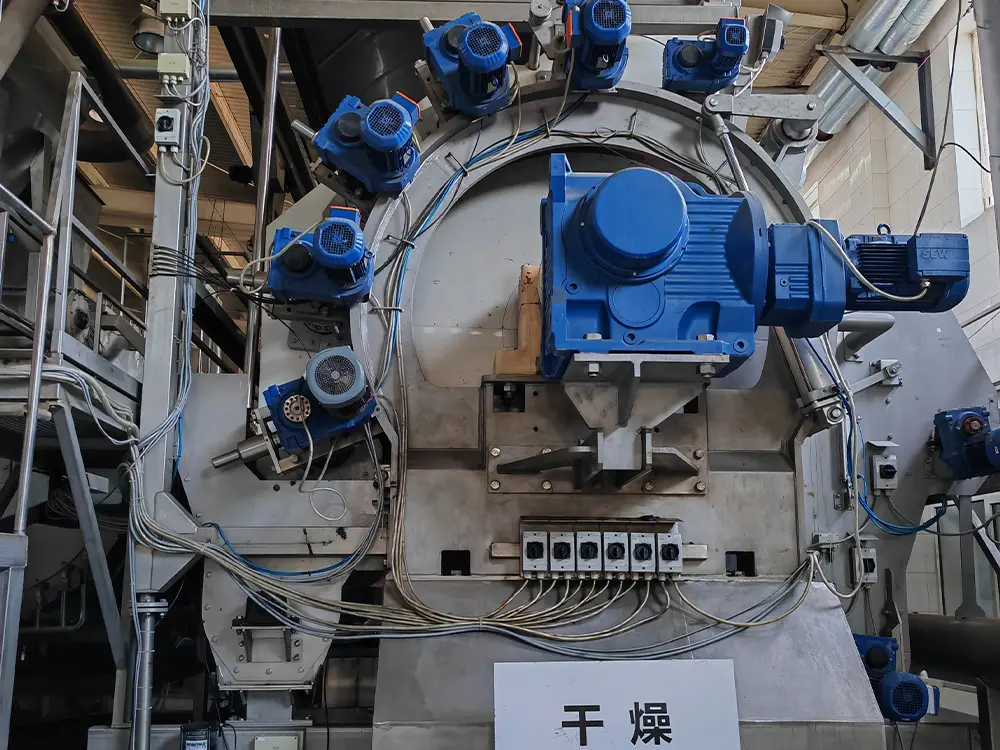

Drum dryer with low water and energy consumption

Product presentation

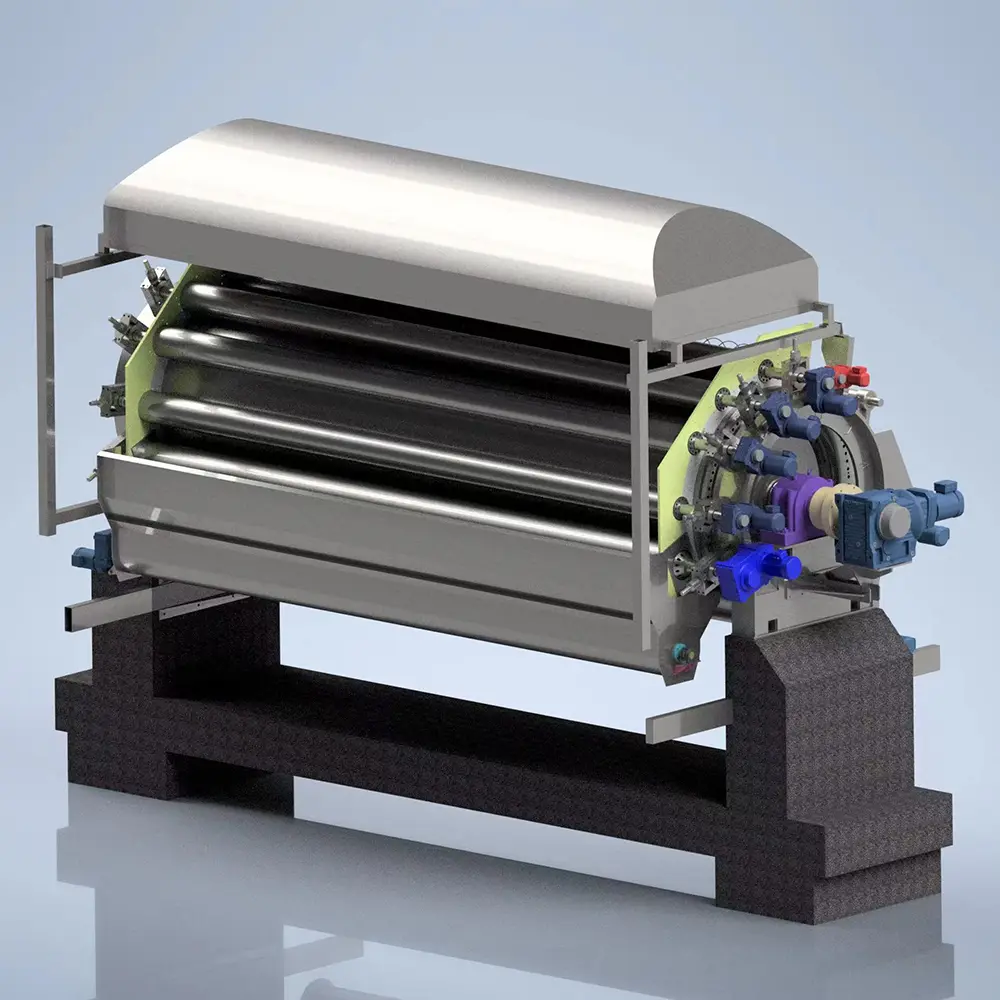

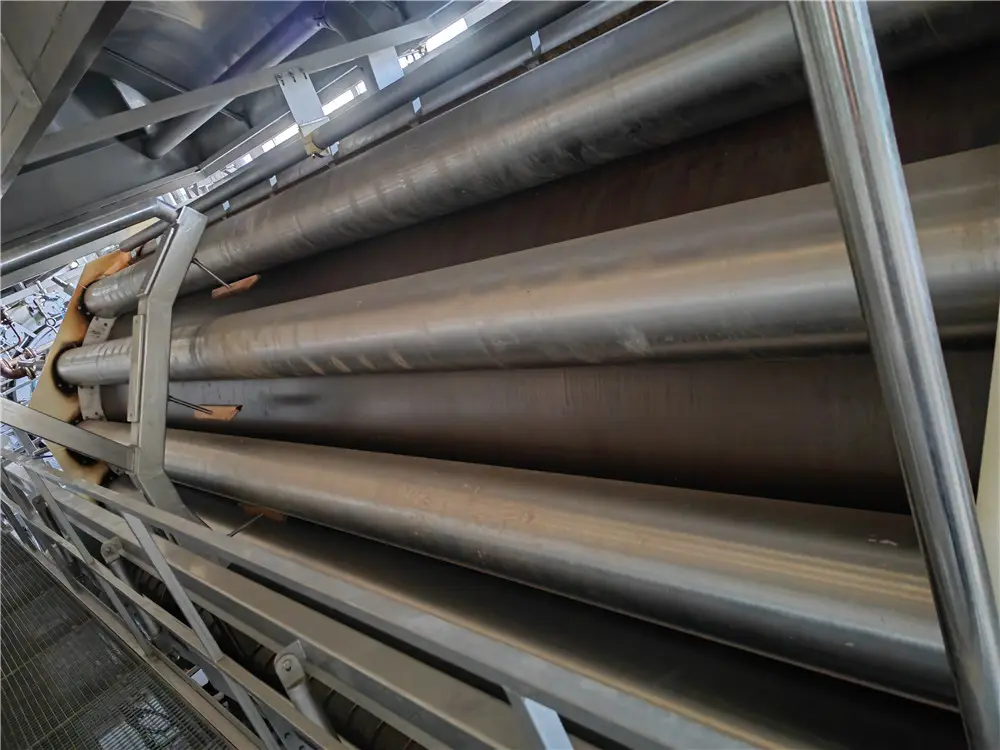

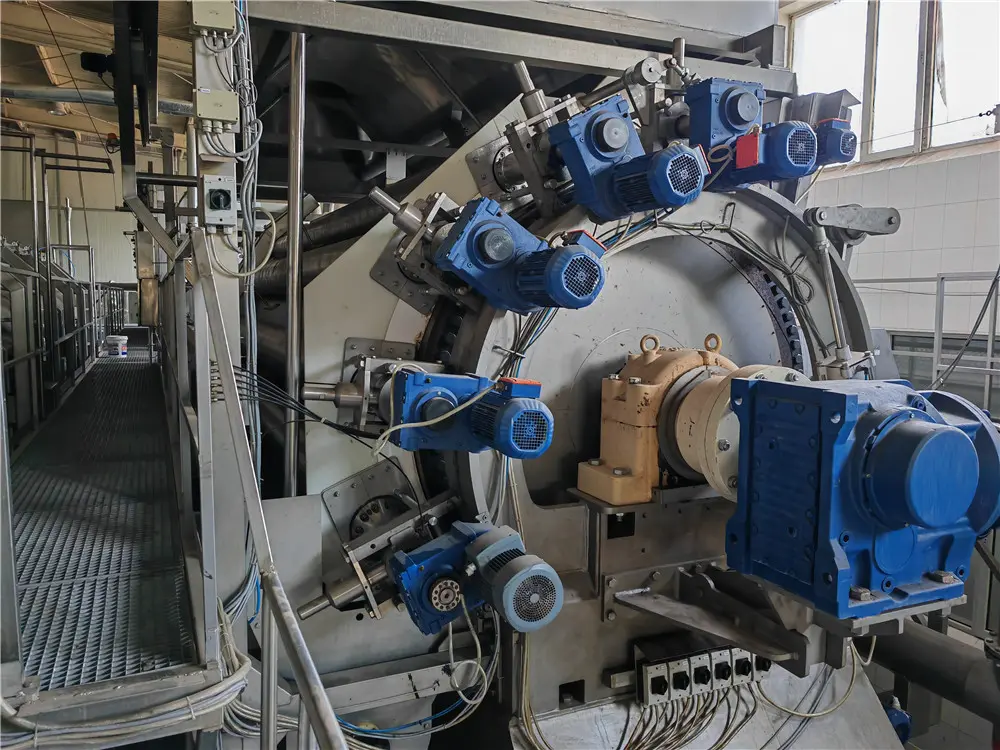

When the product has passed the last satellite roll, it passes under the drum dryer and whilst under constant temperature loses the larger part of its water. For this reason a perforated tube has been mounted at the ascending side of the drum dryer. This tube is connected directly to a ventilator, which suctions the remainder of the water vapour. At the last ascending part of the tube the temperature rises, as a result of this the product falls from the drum and is scraped off by a knife.

The knife has an oscillating movement, to reduce the chance of damaging the drum dryer with grooves. Furthermore, the knife can be quickly replaced and can be used on the upper as well as on the lower side. If so required, the knife can be raised with the aid of air cylinders, mounted on the outer sides. These air cylinders also keep the knife pre-tensioned on the drum dryer, in order to maintain a well scraping movement.

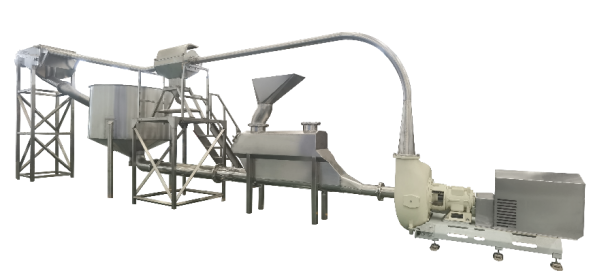

The dry film drops into the flake screw. This broken blade auger grinds the film into smaller flakes. A pneumatic discharge system or transport screw carries off and collects the flakes. Subsequently the flakes enter the grinder, where the required diameter of the flake is obtained by placing the correct sieve. The flake screw as well as the grinder are optionally available.

Parts, which come into contact with the product are made of stainless steel.

Advantage

1. Drying mashed potatoes to obtain potato flakes, is an often used application of the drum dryer, during which the drying process is relativelly simple.

2. Stainless Steel Construction, Meets ASME Code Clearences for Cleaning. It is designed and manufactured for years of top production.

Parameter

| Capacity | 450-680kg/hour |

| Dimension drum | 1500-1800mm |

| Length drum | 4800-6100mm |

| Maximum working pressure | 10 bar |

description2