Potato chips are a favorite snack worldwide. The process of making them begins with slicing the potatoes. This is where the Potato Chips Cutting Machine comes into play. According to industry expert Dr. Emily Smith, "The right cutting machine can significantly affect the chip’s texture and crispness."

These machines vary in design and functionality. Some are manually operated, while others are fully automated. Efficiency is key in any production line. However, many businesses still struggle with consistency in slice thickness. An uneven cut may lead to varying frying times. This can result in chips that are either burnt or too chewy.

Investing in a high-quality Potato Chips Cutting Machine can improve product quality. Yet, not all machines are perfect. Sometimes, they fail to meet the required specifications. Regular maintenance is essential for optimal performance. Manufacturers must continue to innovate and address these challenges to meet consumer demands.

A potato chips cutting machine is a device designed to slice potatoes into thin, even pieces. This equipment streamlines the process of making crispy chips. It dramatically reduces manual labor, offering a consistent result each time. This consistency is quite important in commercial settings.

The machine works by feeding whole potatoes through a chute. Blades cut the potatoes at high speed. Some machines allow for different thickness settings. This feature lets operators customize their chips according to preferences. The result is impressive: perfectly sliced potatoes ready for frying.

However, not all machines yield flawless results. Sometimes, the thickness is uneven, leading to inconsistent cooking. Operators must keep the blades sharp for optimal performance, which requires regular maintenance. If neglected, chips may turn out soggy or unevenly cooked. This aspect of potato chips production invites reflection on the balance between speed and quality.

| Feature | Description |

|---|---|

| Machine Type | Automatic or Semi-Automatic |

| Capacity | 100 kg to 1000 kg per hour |

| Cutting Thickness | 1 mm to 5 mm |

| Material | Stainless Steel |

| Power Consumption | 1 kW to 5 kW |

| Features | Adjustable Speed, Easy to Clean, Safety Features |

| Usage | Commercial Potato Chips Production |

| Maintenance | Regular Cleaning and Lubrication Required |

| Safety Standards | Complies with International Safety Regulations |

The history of potato chips cutting machines dates back to the mid-19th century. The first commercial chips were made by hand, often resulting in uneven slices. This lack of uniformity affected texture and flavor. As demand grew, it became crucial to develop efficient slicing methods. The introduction of manual and automatic machines transformed production.

In the late 20th century, innovations focused on speed and consistency. Data from industry reports indicate that automated machines increased production rates by over 50%. Efficient machines helped businesses meet rising demand and improve profitability. Today, many factories use advanced technology, including laser cutting, to ensure precision.

Tip: Investing in quality cutting machines can reduce waste. Properly sliced chips absorb less oil during frying, enhancing flavor. Remember, machine upkeep is vital for consistent performance. Regular maintenance can prevent costly downtimes. Always monitor the machine's blades; dull blades can lead to uneven cuts. Streamlining the slicing process not only boosts production but also affects the final product.

A potato chips cutting machine is essential in snack production. This machine automates the slicing of potatoes into uniform pieces. Consistency is key; it ensures even cooking and crunch.

Key components include the feeding system, cutting blades, and control panel. The feeding system directs potatoes smoothly into the cutting area. According to industry data, efficient feeding reduces waste by 15%. Blades are typically adjustable, allowing for various chip thicknesses. Precision in cutting can enhance the texture significantly.

Many machines now integrate advanced controls. These systems help operators adjust slicing speed and thickness on the fly. A 2023 market report notes that 30% of manufacturers prefer models with user-friendly interfaces. However, some machines can malfunction with frequent use. Maintenance is crucial but often overlooked. Operators should regularly inspect and replace worn blades to ensure optimal performance.

This chart illustrates key performance specifications of a typical potato chips cutting machine, including speed, power consumption, cutting thickness, and maintenance frequency. Understanding these metrics helps in optimizing production processes.

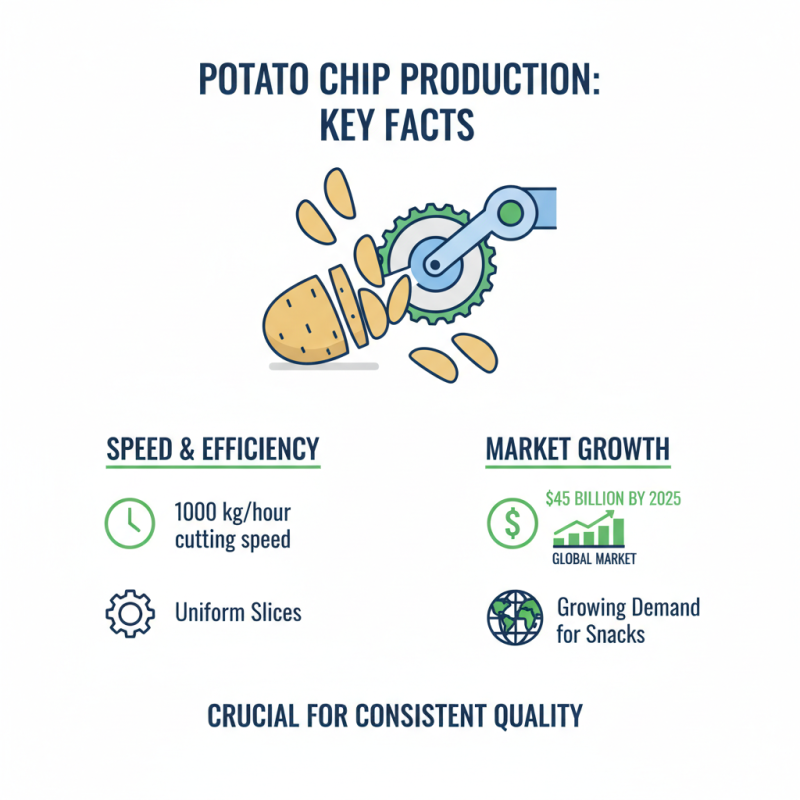

Potato chips cutting machines play a crucial role in the snack food industry. These machines swiftly slice raw potatoes into uniform pieces, essential for ensuring consistent final products. With a cutting speed of up to 1000 kg per hour, they enhance productivity significantly. According to industry data, the global potato chips market is expected to reach $45 billion by 2025, indicating a growing demand for efficient production methods.

The operation of these machines involves several key processes. Potatoes are first fed into a hopper, where they are washed and peeled. Next, they pass through a cutting mechanism, typically composed of stainless steel blades. These blades can be adjusted to create various slice thicknesses, catering to diverse consumer preferences. Recent reports highlight that many manufacturers are exploring automation to improve efficiency further, yet the challenge of maintaining quality remains paramount.

Despite these advances, not all machines meet quality standards consistently. Some may produce uneven slices, leading to issues in frying and seasoning. Operators must regularly monitor blade sharpness and machine calibration. This reflection points to the importance of ongoing training and maintenance in a competitive market that values both speed and quality.

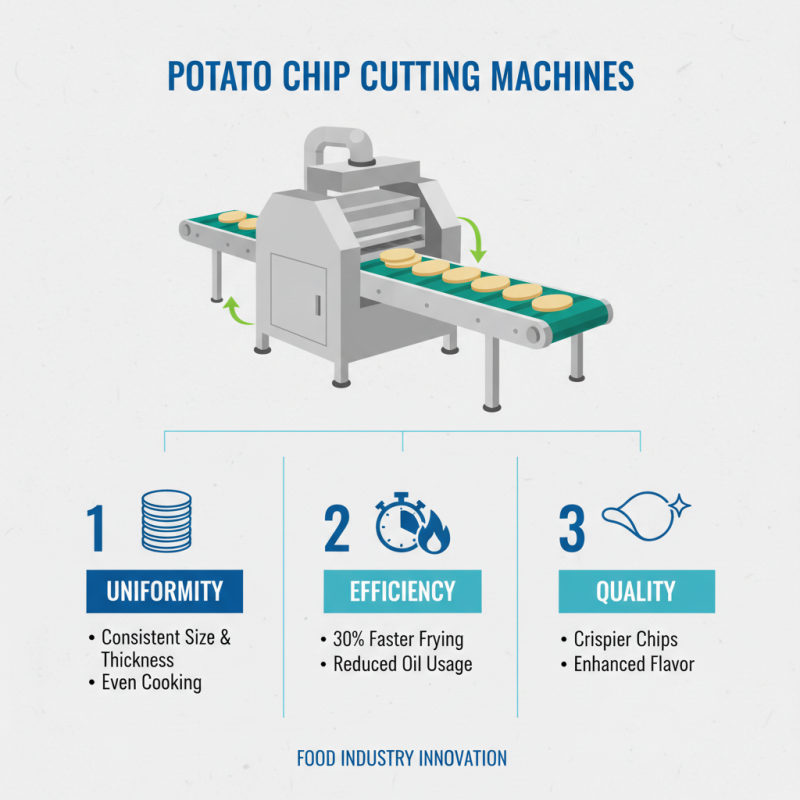

Potato chips cutting machines play a crucial role in the food industry. They ensure consistency in size and thickness. This directly impacts cooking time and flavor absorption. According to industry reports, uniform potato slice thickness can enhance frying efficiency by up to 30%. This leads to crispier chips and reduced oil usage.

Using these machines, businesses can also cater to varying customer preferences. Some enjoy thicker cuts, while others prefer thinner slices. Such versatility allows producers to offer diverse products, appealing to a broader market. Furthermore, automation in slicing minimizes labor costs. The potential for less waste is significant, as precise cutting reduces the number of imperfect chips.

However, relying heavily on machinery might lead to challenges. Maintenance becomes essential to ensure consistent quality. Breakdowns can halt production entirely, resulting in lost revenue. Additionally, not all machines can handle the same potato varieties. Some may struggle with irregular shapes or sizes, affecting output. Continuous assessment of equipment efficiency is vital for long-term success.