The demand for snack foods, particularly potato chips, continues to rise, with the global potato chips market projected to reach $43.2 billion by 2027, according to recent industry reports. As consumers increasingly seek out diverse and high-quality snacks, small-scale entrepreneurs have a unique opportunity to enter this lucrative market with a Small Scale Potato Chips Machine. This compact solution allows businesses to produce fresh and flavorful chips on demand, catering to local tastes and preferences. By leveraging the advantages of small-scale production, entrepreneurs can customize flavors and packaging, resulting in enhanced consumer appeal. In 2023, maximizing profits with these machines is not just about production efficiency but also involves strategic marketing, cost management, and product innovation. This blog will provide seven essential tips that can help small-scale operators optimize their operations and increase profitability in a competitive landscape.

In today's competitive market, understanding the demand for small scale potato chips is crucial for maximizing profits. With a growing trend towards snacking and consumers seeking healthier alternatives, the potato chip industry has seen significant growth. This shift means that small scale producers can tap into niche markets by offering unique flavors, organic options, or even gluten-free products to cater to health-conscious buyers. By aligning your product offerings with current consumer preferences, businesses can effectively stand out in a crowded marketplace.

Additionally, staying abreast of seasonal trends can further enhance demand. For instance, during holidays or local festivals, there tends to be an increase in snacking, providing an excellent opportunity to boost sales. Establishing strong marketing strategies, including social media engagement and local partnerships, can also help raise awareness of your products. Understanding which demographics are most likely to purchase your chips will allow entrepreneurs to tailor their marketing efforts, ensuring optimal reach and impact.

| Tip No. | Tip | Market Demand Insight | Profit Potential (%) |

|---|---|---|---|

| 1 | Choose High-Quality Potatoes | Consumers prefer better quality snacks | 15-20% |

| 2 | Optimize Flavor Options | Diverse flavors attract more customers | 10-15% |

| 3 | Invest in Branding | Strong branding increases customer loyalty | 15-25% |

| 4 | Utilize Social Media Marketing | Engagement on platforms boosts sales | 20-30% |

| 5 | Enhance Packaging | Appealing packaging attracts buyers | 10-15% |

| 6 | Monitor Competitors | Stay ahead of market trends | 5-10% |

| 7 | Focus on Quality Control | Consistency maintains customer satisfaction | 15-20% |

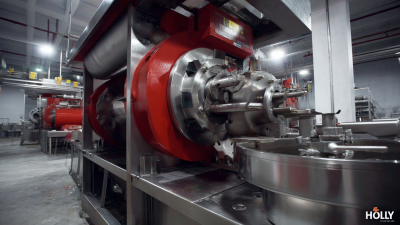

When selecting the right potato chips machine, it’s crucial to consider efficiency and output, especially in a growing market projected to reach $45 billion globally by 2027. A machine that can process potatoes quickly while maintaining quality can significantly impact your profitability. Look for models that offer adjustable thickness settings, allowing you to cater to diverse customer preferences while optimizing processing time.

One essential tip is to invest in machines with advanced frying technology. Studies show that air frying techniques can reduce oil usage by up to 50%, boosting your profit margins. Additionally, consider machines that are designed for easy cleaning and maintenance, as this can save you valuable downtime.

Lastly, prioritize machines equipped with energy-efficient motors and features that minimize waste. According to industry reports, optimizing energy consumption can lead to a 20% reduction in operational costs. By making informed choices on the right potato chips machine, you position your business for sustained growth in the competitive snack food sector.

When operating a small scale potato chips machine, optimizing production processes is key to achieving higher profit margins. One effective strategy is to streamline the preparation stage by carefully selecting the best quality potatoes. This not only enhances the flavor of the chips but also reduces waste and maximizes yield. Implementing a standardized cutting technique ensures uniformity in chip size, leading to even cooking and a consistent product that appeals to consumers.

Another crucial aspect of process optimization is temperature and timing control during frying. Investing in a quality frying system that maintains consistent heat can significantly improve the texture and taste of the chips. Additionally, experimenting with different frying times can help determine the perfect balance that prevents overcooking while maximizing crispness. Utilizing oil filtration systems can extend the life of frying oil, further reducing costs and improving the quality of the final product. By focusing on these production optimizations, small scale potato chips manufacturers can effectively enhance their profit margins while delivering a superior product to the market.

Effective marketing strategies are crucial for maximizing profits when operating a small scale potato chips machine. One of the most potent approaches is leveraging social media platforms. With their growing significance, these platforms provide an excellent opportunity to reach a broader audience. Engaging content, such as behind-the-scenes videos of the chip-making process or customer testimonials, can foster a community around your brand. Regular updates and interactive posts not only keep your brand in the public eye but also encourage user-generated content that enhances authenticity.

Another effective strategy is to focus on customer retention rather than solely on acquiring new customers. A slight increase in repeat purchase rates can greatly impact profit margins. Implementing customer loyalty programs can incentivize existing buyers to return more frequently. Additionally, holiday marketing campaigns can boost sales during peak times. Tailoring promotions around festive occasions creates excitement and prompts seasonal purchases, making customers feel special while driving revenue. By combining these strategies, small scale potato chip businesses can attract more customers and significantly enhance profitability.

When operating a small-scale potato chips machine, managing costs effectively is paramount for sustainable growth. The first step is to analyze your raw material costs. Sourcing high-quality potatoes at bulk rates can significantly decrease your per-unit expense. Establishing relationships with local farmers or suppliers not only ensures fresh ingredients but also helps negotiate better prices. Consider seasonal variations and fluctuating market prices while planning your purchases to maximize savings.

Additionally, resource management extends beyond just ingredients. Streamlining production processes can improve efficiency and reduce waste. Regular maintenance of your potato chips machine ensures that it runs at optimal capacity, preventing costly downtime and extending its lifespan. Training your staff in efficient production techniques can boost output and minimize by-products. Moreover, incorporating energy-efficient practices can lower operational costs in the long run. A focus on sustainability not only contributes to profit maximization but also builds a responsible brand that appeals to a growing market of environmentally-conscious consumers.