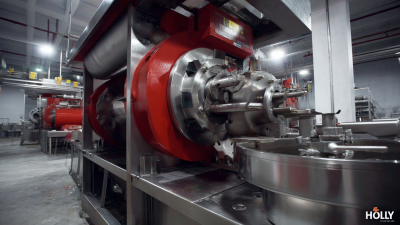

The food processing industry is continually evolving, with a significant focus on enhancing productivity and efficiency. One of the pivotal innovations that has emerged in this field is the "Automatic Steam Peeler," an advanced machine designed to streamline the peeling process, particularly for fruits and vegetables. According to a report by Market Research Future, the global food processing equipment market is projected to reach $83 billion by 2027, with automation playing a crucial role in this growth.

The Automatic Steam Peeler not only reduces labor costs but also minimizes waste, ensuring a higher yield of usable product. With time-saving capabilities and the ability to handle large volumes, this technology aligns perfectly with the industry's needs for efficiency and sustainability. As businesses strive to maintain competitive edges while meeting growing consumer demands, implementing such automated solutions has become essential.

The impact of automatic steam peelers on production rates in the food processing industry cannot be overstated. Modern steam peeling technology dramatically enhances processing speed by effectively removing the skins of vegetables and fruits with minimal damage to the product. According to industry reports, the adoption of steam peeling systems can increase production rates by 20-50%, allowing food processors to manage higher volumes while maintaining quality. This efficiency is particularly beneficial in high-demand sectors, such as frozen potato products, where even marginal gains in speed can lead to significant increases in output.

Moreover, the reduction of food waste is a crucial aspect of using automatic steam peelers. Traditional peeling methods often result in substantial waste, which translates to financial losses for processing companies. Recent studies suggest that implementing advanced steam peeling solutions can reduce food waste by up to 30%, turning what was once discarded into usable product. By enhancing both efficiency and yield, automatic steam peelers have proven to be a game-changer for businesses looking to optimize their operations and improve their bottom line in a competitive market.

In the food processing industry, labor costs can significantly impact overall efficiency and profitability. Implementing an automatic steam peeler can reduce workforce requirements by up to 30%, effectively addressing these rising expenditures. This innovative technology not only accelerates the peeling process but also enhances the precision and consistency of the end product. By automating this labor-intensive task, businesses can reallocate staff to more value-added activities, creating a more efficient and productive work environment.

As automation continues to make inroads into various sectors, its benefits are evident in fast-food kitchens and food processing facilities alike. Many establishments are adopting automated solutions to streamline workflows and minimize manual labor. The success of automatic peelers, now exported to numerous countries, demonstrates a growing trend toward integrating technology to meet operational challenges. With the ability to significantly reduce prep times and improve output quality, automatic steam peelers stand as a testament to the transformative potential of automation in modern food processing businesses.

| Metrics | Before Automation | After Automation | Percentage Improvement |

|---|---|---|---|

| Labor Hours Per Batch | 100 hours | 70 hours | 30% |

| Cost of Labor Per Batch | $1,500 | $1,050 | 30% |

| Throughput (Batches Per Hour) | 2 | 3 | 50% |

| Peeling Accuracy (%) | 85% | 95% | 11.76% |

| Returns Due to Peeling Defects (%) | 5% | 2% | 60% |

Steam technology is revolutionizing food processing by enhancing product quality while retaining nutritional value. Automatic steam peelers utilize precise temperatures and timing, ensuring that the outer layers of fruits and vegetables are removed without compromising the integrity of the product inside. This method not only maintains essential vitamins and minerals but also improves the overall flavor and texture, making for a healthier end product that appeals to consumers.

**Tips for Efficient Use of Steam Technology:**

1. **Maintain Optimal Temperature Control:** To maximize the nutritional benefits, ensure that your steam peeler operates at the right temperature. Excessive heat can lead to nutrient loss, so calibrate your equipment regularly.

2. **Optimize Timing:** Experiment with different timings to find the sweet spot that effectively peels without overcooking the produce. Using a timer can help standardize the process and maintain consistency across batches.

3. **Regular Maintenance:** Keep your steam peeler in top condition with routine checks and cleaning. This not only extends the life of the equipment but also ensures optimal performance, so your products always meet quality standards.

By harnessing steam technology, food processors can significantly elevate the quality of their offerings, ultimately leading to higher customer satisfaction.

In the food processing industry, energy efficiency is crucial for both economic viability and sustainability. According to the U.S. Department of Energy, food processing accounts for approximately 15% of total energy consumption in the manufacturing sector. Traditional peeling methods, which often rely on manual labor or inefficient machinery, can lead to significant energy waste. In contrast, automatic steam peelers utilize high-pressure steam to remove skins effectively while consuming less energy. A study from the Food Processing Association indicates that these machines can reduce energy usage by up to 50% compared to older methods.

In the food processing industry, energy efficiency is crucial for both economic viability and sustainability. According to the U.S. Department of Energy, food processing accounts for approximately 15% of total energy consumption in the manufacturing sector. Traditional peeling methods, which often rely on manual labor or inefficient machinery, can lead to significant energy waste. In contrast, automatic steam peelers utilize high-pressure steam to remove skins effectively while consuming less energy. A study from the Food Processing Association indicates that these machines can reduce energy usage by up to 50% compared to older methods.

Moreover, automatic steam peelers not only enhance energy efficiency but also improve productivity. While manual peeling can take several hours and require a significant workforce, automatic steam peelers can process large quantities of produce rapidly, with some models achieving peeling speeds of up to 200 kg per hour. This efficiency translates to lower labor costs and increased throughput, allowing businesses to meet rising consumer demand more effectively. Consequently, the investment in automatic steam peeling technology presents a compelling opportunity for food processors seeking to optimize their operations and minimize their carbon footprint.

In the food processing industry, meeting regulatory standards for food safety is paramount. Automatic steam peelers not only enhance efficiency but also play a crucial role in ensuring compliance with these standards. According to a report by the Food Safety and Inspection Service (FSIS), approximately 48 million people in the U.S. experience foodborne illnesses each year, highlighting the importance of stringent food safety measures. By minimizing the potential for contamination during the peeling process, automatic steam peelers help businesses align with regulations set forth by organizations like the FDA and USDA.

Tips: Implement regular maintenance checks on your automatic steam peeler to ensure optimal performance and reduce the risk of contamination. Training staff on the proper usage and hygiene standards associated with the equipment can further enhance food safety compliance.

Moreover, the use of steam peeling can reduce the likelihood of chemical residues that may be present with manual peeling methods. A study by the Institute of Food Technologists indicates that steam peeling allows for a reduction in the use of chemical detergents, which are often subject to stringent regulations. By embracing automatic steam peelers, food processing businesses can not only boost their production efficiency but also uphold high safety standards, thus ensuring consumer trust.

Tips: Stay updated on local and federal food safety regulations to adapt your processes as needed, ensuring your automatic steam peeler is compliant with the latest standards.