Setting up a Potato Flakes Processing Line requires careful planning. The right equipment must be selected to ensure efficiency. The entire process involves several important stages. Each stage has its own challenges and potential pitfalls.

Selecting the right machinery can be daunting. It is crucial to understand the required capacity. Additionally, the layout of the processing line affects workflow. Poor arrangement can lead to delays and increased costs.

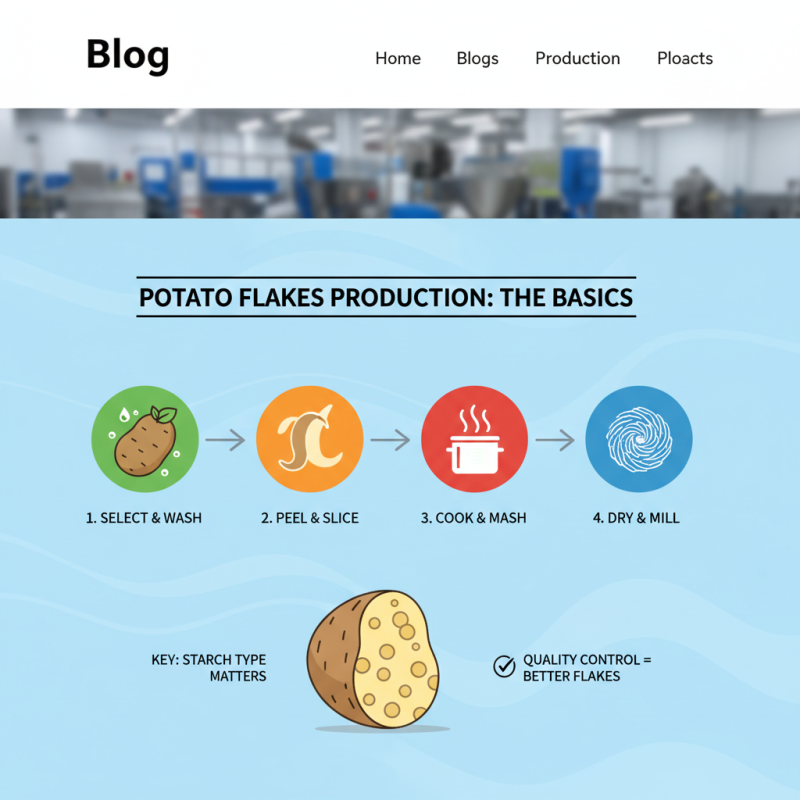

Quality control is another key aspect. Ensuring that the potato flakes meet industry standards demands constant vigilance. Failures in quality can harm market reputation. Thus, regular assessments are essential. Reflecting on these components can lead to continuous improvement in your Potato Flakes Processing Line.

Understanding the basics of potato flakes production is crucial for an efficient processing line. The journey begins with selecting high-quality potatoes. The variety matters, as some yield better flakes than others. Washing the potatoes thoroughly is essential. Any dirt left on the skin can affect taste and quality.

Next, the peeling process must be efficient. Excessive waste can lead to higher costs. After peeling, potatoes are sliced into uniform pieces. This ensures even cooking and drying. Cooking improves texture and flavor, but overcooking can ruin the batch. It's a delicate balance that requires constant monitoring.

Drying is another critical stage. Flakes must be dehydrated thoroughly to ensure shelf stability. Inadequate drying leads to spoilage later on. The grind size of the dried flakes also impacts the final product. Too coarse, and they won't rehydrate well; too fine, and they may clump. Each step requires attention. Mistakes here can cascade through the process. Consistent quality is hard to achieve without careful control over every detail.

Setting up a potato flakes processing line requires key equipment to ensure efficiency. The process starts with high-quality raw potatoes. These must be washed thoroughly to remove dirt and impurities. The washing area needs to be well-designed for rapid processing. Each washed potato should be examined for defects before peeling.

The peeling stage is crucial. A good peeler can remove skins without wasting too much potato flesh. According to industry reports, an efficient peeler can reduce waste by up to 10%. After peeling, the potatoes go through cooking and mashing. Proper control of temperature and time during these stages is essential to maintain flavor and texture.

Tips: Consider using sensors for precise temperature control. They can help reduce inconsistencies. Regular maintenance of each machine is necessary. Machines can experience wear over time, affecting performance. Always keep a checklist for machine inspection.

The dried flakes then need to be packaged properly. Packaging should maintain freshness while being easy to store. An efficient packing line may incorporate automated machinery. This speeds up the process but can require higher initial investment. Balancing efficiency with cost is key to overall success.

| Equipment | Purpose | Specifications | Estimated Cost (USD) |

|---|---|---|---|

| Peeling Machine | To remove the skin of potatoes | Capacity: 500 kg/h | $8,000 |

| Slicing Machine | To cut potatoes into uniform slices | Thickness: adjustable from 1-10 mm | $5,000 |

| Blancher | To blanch potato slices to inactivate enzymes | Temperature: 85°C, Time: 2-5 min | $10,000 |

| Dehydration Machine | To remove moisture from blanched slices | Capacity: 300 kg/h, Efficiency: 90% | $15,000 |

| Milling Machine | To mill dried potato slices into flakes | Output Mesh Size: 60-80 mesh | $7,000 |

| Packing Machine | To package potato flakes for distribution | Speed: 30 bags/min, Bag Size: customizable | $12,000 |

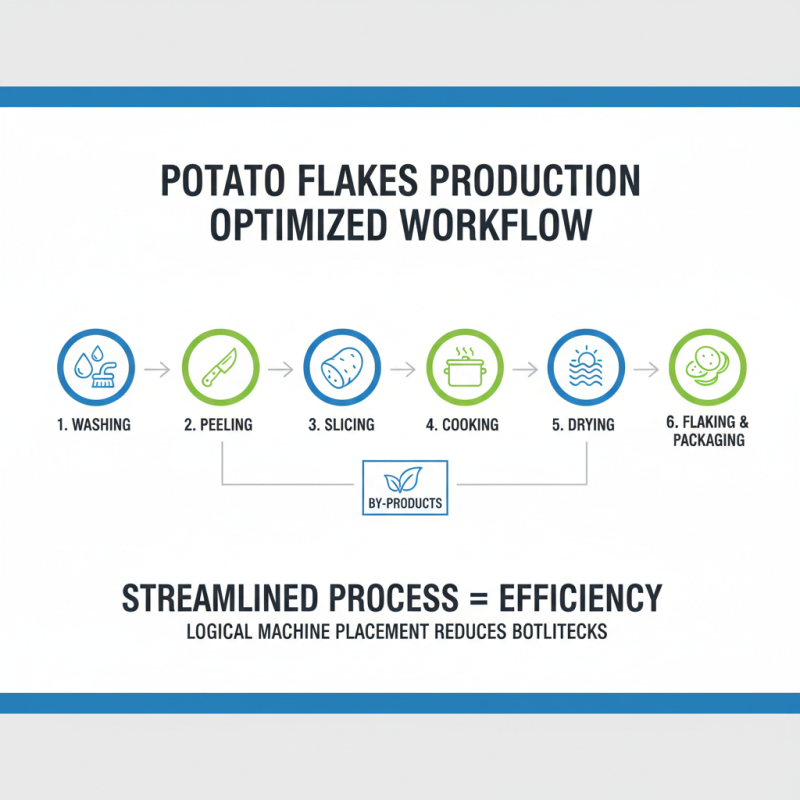

Setting up a potato flakes processing line requires careful planning. Begin with understanding the overall layout. The space should allow for smooth movement between each processing station. Consider the flow of materials. Potatoes should easily move from washing to peeling, then to slicing and cooking. This layout reduces bottlenecks and improves efficiency.

Next, focus on equipment placement. Each machine needs enough room for operation and maintenance. Ensure that the area is well-ventilated. It helps prevent overheating of machines. Also, think about power supply and water sources. They should be easily accessible for all stations. Avoid cluttering the space with unnecessary items. This could hinder workflow.

Finally, assess the design regularly. Are safety protocols being followed? Are staff members trained effectively? Conducting regular reviews can help identify issues. Make adjustments based on feedback from the crew. This collaborative approach can lead to a more efficient processing line. It's important to stay flexible and open to changes as you optimize the workflow.

Setting up a potato flakes processing line requires careful planning to optimize workflow and manage resources effectively. Start by designing a layout that reduces bottlenecks. Ensure that machines are placed logically, moving from washing to peeling, slicing, cooking, and drying. Consider the flow of both potatoes and by-products. A simple, clear path reduces the chance of errors.

Resource management is crucial in this process. Invest in equipment that offers durability and efficiency. Regular maintenance checks are necessary to avoid unexpected downtimes. It's also important to train staff adequately. Miscommunication can lead to wasted materials and time.

You may face challenges in balancing production speed and quality. Rushing processes might lead to inconsistency in the final product. Regularly assess your workflow and make adjustments based on feedback. Engaging with your team can provide valuable insights. Reflection on these aspects may lead to better practices over time.

Quality control is vital in potato flakes manufacturing. The process starts with raw potato selection. High-quality potatoes contribute to the final product quality. Inspecting for defects, size, and color is critical. Damage and rot can compromise the entire line.

During the processing stage, frequent checks on temperature and time are necessary. Overcooking can lead to a burnt flavor. Under-processing may produce a raw taste. Both scenarios need immediate attention. Regular calibration of equipment helps maintain consistent quality.

Packaging is another crucial point. Flakes must be stored in moisture-proof packaging. This prevents spoilage and maintains crunchiness. Visual inspections on packaging integrity are key. Even minor tears can lead to contamination. These details matter significantly. Addressing them can enhance overall product quality.