The food processing industry is constantly seeking methods to enhance efficiency and reduce waste. One notable innovation that has emerged is the Automatic Steam Peeler, a device that integrates steam technology to streamline the peeling process for various fruits and vegetables. According to a recent report by MarketsandMarkets, the global food processing equipment market is projected to reach USD 72.4 billion by 2025, highlighting the growing demand for automation in food production. Traditional peeling methods often result in significant product loss and labor intensiveness, leading to increased operational costs. In contrast, the Automatic Steam Peeler not only minimizes waste but also boosts production speed, allowing businesses to meet rising consumer demands more effectively. With global food consumption projected to increase by 70% by 2050, investing in advanced equipment like the Automatic Steam Peeler is essential for manufacturers aiming to stay competitive in a rapidly evolving industry.

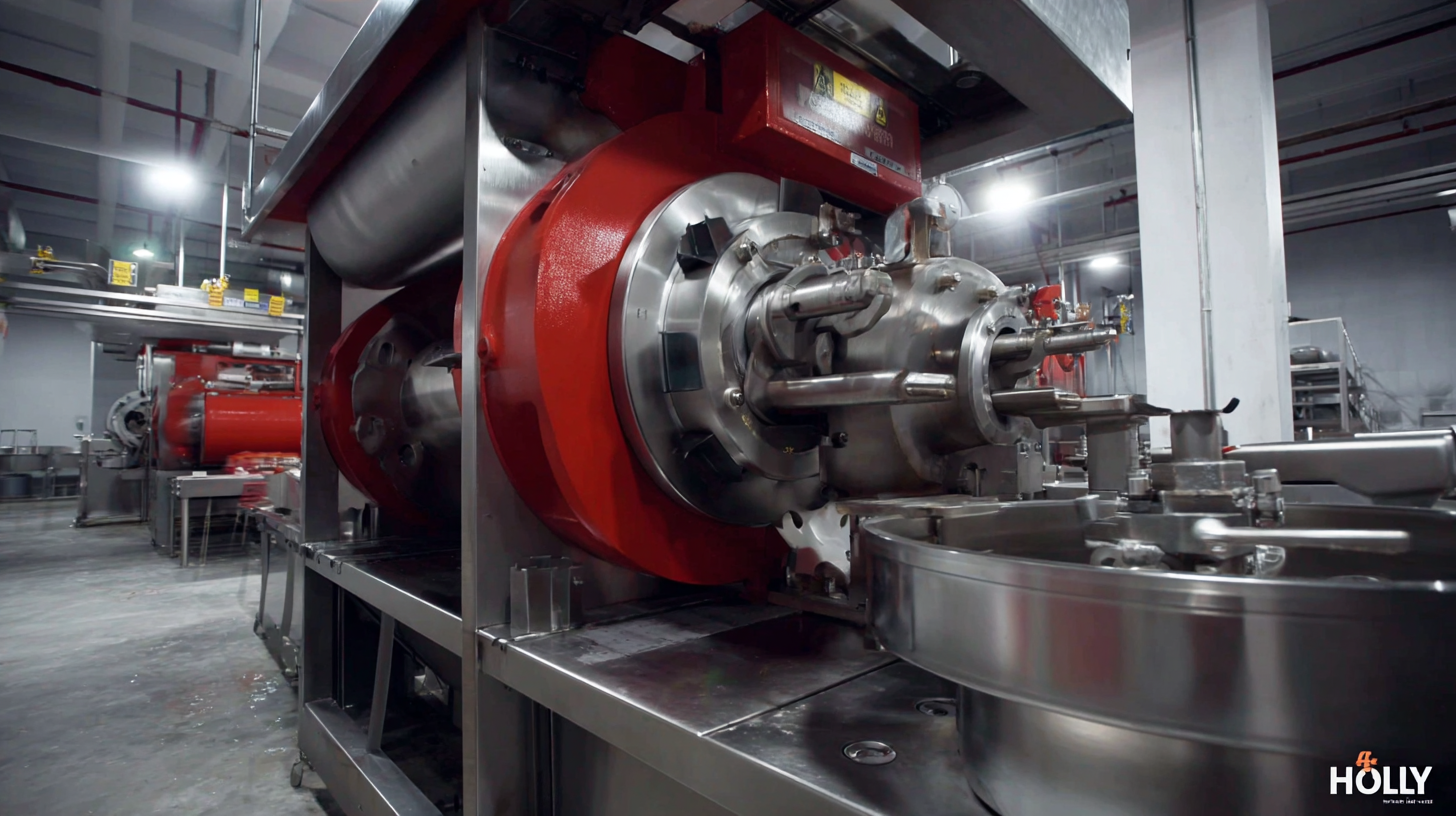

Automatic steam peelers have revolutionized the food processing industry by enhancing efficiency and significantly reducing labor costs. One of the primary benefits of using these machines is their ability to peel fruits and vegetables quickly while minimizing waste. The steam heat softens the skin, allowing for a clean and easy removal without damaging the flesh underneath. This not only ensures a better yield but also maintains the quality and nutritional value of the produce.

Moreover, automatic steam peelers contribute to improved hygiene standards in food processing. Traditional peeling methods often involve manual handling, which can introduce contaminants. In contrast, automatic machines deliver a consistent and sanitary peeling process, thereby reducing the risk of foodborne illnesses. The integration of these peelers into production lines can lead to greater productivity and speed, enabling manufacturers to meet the growing demand for processed food while adhering to strict safety regulations.

| Parameter | Details |

|---|---|

| Peeling Efficiency | Up to 95% peeling efficiency, reducing waste. |

| Time Consumption | 15-20% reduction in processing time compared to manual methods. |

| Labor Costs | Potential labor savings of 30% due to automated operation. |

| Product Quality | Improved product quality with less mechanical damage. |

| Energy Consumption | Reduction in energy consumption by 20% per unit processed. |

| Safety | Enhanced safety features reduce risk of injuries compared to manual peeling. |

Steam peeling is an innovative and efficient technique widely used in the food processing industry. This method is particularly effective for a variety of foods that benefit from quick skin removal without compromising their texture and flavor. Vegetables such as tomatoes, potatoes, and sweet potatoes are among the best candidates for steam peeling. The process works by applying steam to the skins, causing them to loosen, making the peeling task less labor-intensive and reducing waste significantly.

Fruits like peaches and plums also excel in steam peeling due to their thin skins. The natural sugars and flavors in these fruits remain intact, ensuring that the end product retains its quality. Steam peeling not only enhances the visual appeal of these foods but also preserves their nutritional value, making it an ideal choice for food processors focused on efficiency and quality. As the demand for pre-processed and ready-to-eat foods continues to rise, adopting steam peeling technology can lead to improved productivity and reduced processing times for various types of produce.

When it comes to efficient food processing, the choice of equipment plays a pivotal role, especially with automatic steam peelers. These machines have become indispensable in the food industry, helping to significantly reduce labor costs and processing time. Reports suggest that utilizing automatic peelers can decrease peeling times by up to 30%, enhancing overall productivity. However, selecting the right steam peeler involves understanding its key features.

One important aspect to consider is the peeling capacity. Look for machines with adjustable settings to accommodate various volumes and types of produce. Such versatility ensures that the peeler can adapt to different operational scales, from small-scale processors to larger manufacturing plants. Additionally, pay attention to the steam temperature control; this feature allows for precise peeling without damaging the food product, ensuring maximum yield.

Tip: Always choose a model that offers easy maintenance options, as this can significantly enhance durability and performance over time. Moreover, consider the energy efficiency of the steam peeler, as choosing a model that consumes less electricity can lead to substantial savings in the long run. With the right automatic steam peeler, companies can streamline their processes and increase their competitive edge in the marketplace.

The peeling of fruits and vegetables is a foundational operation in food processing, influencing both the quality and appeal of the final products. Among the various peeling methods, mechanical, steam, chemical, and manual peeling are the most widely adopted. Each method presents its own set of efficiencies and limitations. For instance, steam peeling has gained popularity due to its ability to process large quantities swiftly while ensuring minimal damage to the product's texture and flavor. In contrast, manual peeling, although labor-intensive and time-consuming, often results in variances in thickness and quality, leading to inconsistencies in the final output.

Recent advancements in peeling technology have also brought about innovations like the combined peeling machine designed for water chestnuts, which utilizes a rotary knife and differential friction belts for effective peeling. Moreover, studies on pulsed electric fields (PEF) treatment indicate potential improvements in the peeling efficiency for produce such as tomatoes and kiwi fruits. Data suggests that while manual methods might yield about 50 kg of peeled produce per hour, automatic steam peeling systems can enhance this output significantly, achieving rates exceeding 500 kg per hour under optimal conditions. This substantial difference underscores the advantages of investing in automatic steam peelers for food processing operations aiming for both efficiency and quality.

Maintaining your automatic steam peeler is essential for ensuring optimal performance and longevity. Regular maintenance not only enhances the efficiency of the peeling process but also minimizes downtime caused by unexpected breakdowns. One of the key tips is to routinely check and clean the steam nozzles. Clogged nozzles can reduce steam pressure, resulting in incomplete peeling. A simple weekly inspection and cleaning with a soft brush can keep them functioning effectively.

Another important aspect of maintenance is monitoring the water quality used in the steamer. Using clean, filtered water prevents mineral buildup and corrosion in the system. It's advisable to replace the water regularly and run a descaling solution through the peeler to maintain optimal performance. Additionally, ensure that all seals and gaskets are in good condition, as worn or damaged components can lead to steam leaks and reduced efficiency. By following these steps, you can significantly extend the lifespan of your steam peeler while ensuring that it operates at peak efficiency.