Choosing the right Potato Chips Packing Machine can be a daunting task. With various options available, it's essential to understand your specific needs. Different machines offer various features and capabilities.

Consider factors like speed, efficiency, and packaging styles. A well-suited packing machine can significantly enhance your production line. However, the ideal choice may seem unclear at times. Suppliers often promote their machines as the best, leading to confusion.

Look for machines that suit your production volume. Don't overlook maintenance needs and availability of spare parts. Sometimes, the cheapest option may not be the best in the long run. Balancing cost and quality is crucial. Ultimately, make a decision that aligns with your business goals.

When considering different types of potato chips packing machines, it’s important to explore various options. Machines can vary in size, speed, and functionality. Some are designed for small batches, while others handle high volume. Think about your production needs and space requirements.

Gravity-fed machines use simple principles. They allow chips to flow into bags effortlessly. However, they may not be suitable for all shapes and sizes of chips. Consider whether your product needs special handling. This is where more advanced machines shine.

Vertical form-fill-seal machines offer flexibility and efficiency. They can package unique chip shapes but may require more maintenance.

Auto-weighing machines can ensure consistency. They provide precise weight for each bag. But, they can be costly and require skilled operators. Balancing budget and efficiency is a crucial aspect here. Evaluate how each machine aligns with your production goals. Reflect on your long-term needs as well. A decision made today can impact your operations tomorrow.

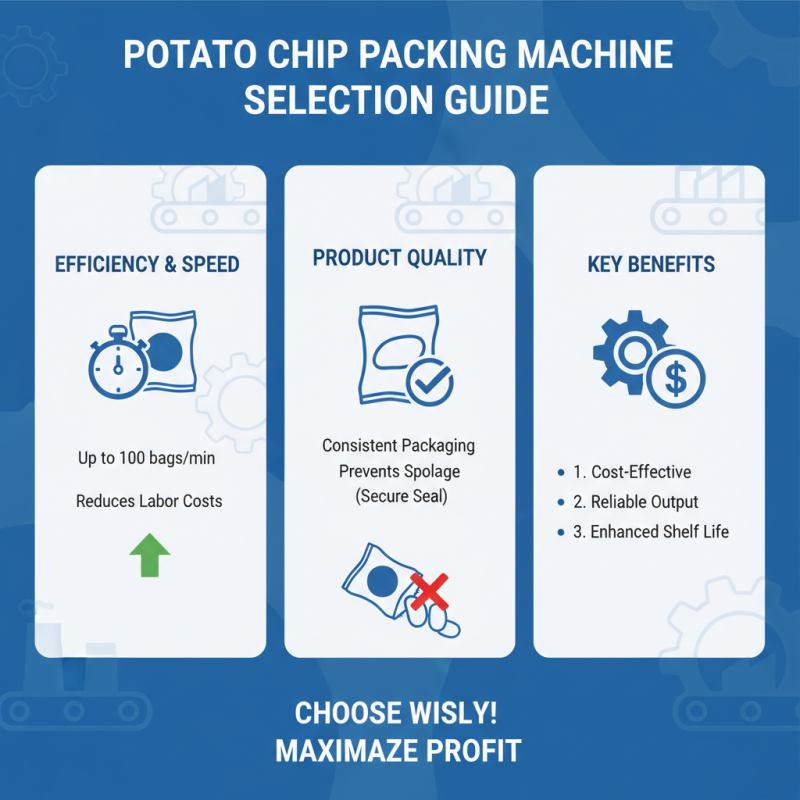

When selecting a potato chips packing machine, consider its efficiency and speed. Studies indicate that modern machines can operate at speeds of up to 100 bags per minute. High efficiency reduces labor costs significantly. A machine that can produce consistent packaging ensures product quality. An inconsistent seal can lead to spoilage.

Another aspect to consider is the machine’s adaptability. The food industry is ever-evolving. A packing machine should accommodate various bag sizes and weights. According to industry reports, flexible machines can lead to a 25% increase in production versatility. However, not all machines offer this benefit. Ensure you invest in technology that meets your future needs.

Moreover, pay attention to the machine’s maintenance requirements. Frequent downtime can be costly. Machines that are easy to maintain can save both time and money. Regular service checks are essential, yet many companies overlook them. This can lead to larger issues down the line. Finally, evaluate the overall cost versus long-term investment. Sometimes cheaper machines lead to higher operational costs. It's a balance between upfront spending and lasting efficiency.

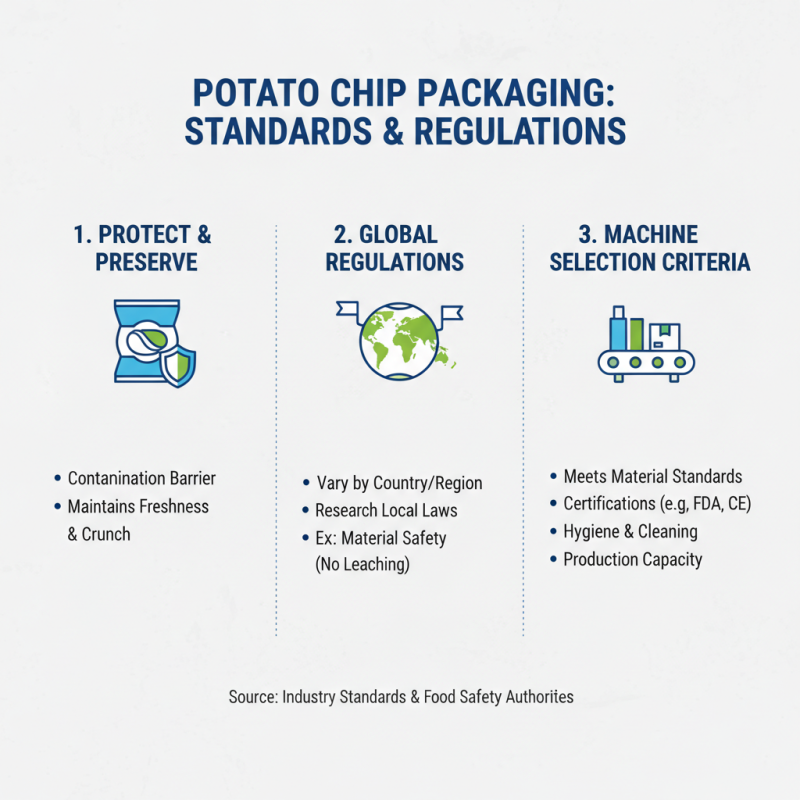

Choosing a potato chips packing machine requires understanding industry standards and regulations. Proper packaging protects the chips from contamination and preserves their freshness. Regulations vary by country and region, making it crucial to research local requirements. For instance, some regions mandate the use of specific materials that don’t leach harmful substances into food.

Additionally, look into the labeling requirements. Many jurisdictions necessitate clear information on ingredients and nutritional content. Failing to meet these standards can lead to fines or product recalls. It's also important to consider eco-friendly packaging options. Sustainability is becoming a priority for consumers, and using recyclable materials can enhance market appeal.

There are challenges in complying with these regulations. Manufacturers must stay updated on changes that could affect their processes. It's easy to become overwhelmed by the details. Taking time to assess current practices is essential. Investing in training for staff can improve adherence to these standards. Continuous improvement is key to success in this competitive market.

Choosing the right potato chips packing machine is crucial for both cost and efficiency. A data-driven approach can help you evaluate various options. Start by analyzing your production needs. Look at the volume of chips you need to package daily. This helps in selecting a machine that meets your requirements without overspending.

Tips: Collect data on your current production rate. Understand your peak seasons to predict future needs. You may find that some machines are overkill. Efficiency should be balanced with cost. A cheaper machine may save money initially but could lead to higher labor costs or increased downtime.

Additionally, consider maintenance and operational costs. Some machines may have lower upfront costs but be costly to maintain. Look for models with good reviews on reliability. Remember, not every machine suits every business. Take time to reflect on your specific needs. Data can guide you, but your experience matters too.

This chart compares the cost and efficiency of various potato chips packing machines. The cost is represented in thousands of dollars, while the efficiency is measured in units produced per hour. This data-driven approach helps in evaluating the best option for your packing needs based on a balance of cost and performance.

Proper maintenance and support are crucial for the longevity of potato chips packing machines. Regularly inspecting machine components is essential. This includes checking seals, belts, and sensors. Small issues can lead to significant downtime. A worn-out seal might cause product leaks. Operators should be trained to identify these problems early.

Creating a maintenance schedule helps prevent unexpected breakdowns. This schedule should cover cleaning, lubrication, and part replacements. Forgetting to clean can lead to contamination. Lubrication reduces friction, extending the machine's life. It's essential to document maintenance activities. Keeping records helps track performance and highlights recurring issues.

Support from knowledgeable technicians is also invaluable. They can provide insights during maintenance visits. Their expertise aids in troubleshooting. Yet, not every problem can be solved immediately. Sometimes, operators must wait for parts. This can be frustrating but is part of the process. Continuous learning about machine functions is necessary for everyone involved.

| Feature | Description | Importance |

|---|---|---|

| Machine Speed | The speed at which the machine can pack potato chips. | High |

| Build Quality | Materials used in construction that affect durability. | High |

| Ease of Maintenance | How easy it is to clean and service the machine. | Medium |

| Support and Training | Availability of assistance and training for operators. | High |

| Energy Efficiency | Amount of energy required for operation. | Medium |

| Versatility | Ability to handle different types of bags and products. | High |