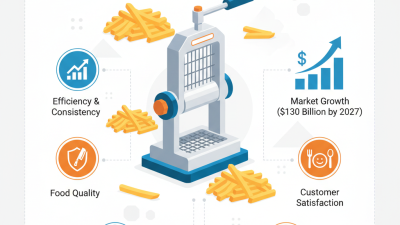

Choosing the right French fries processing machine is crucial for any business aiming to deliver high-quality, delicious fries consistently. Renowned industry expert Mark Thompson, a veteran in food processing technology, emphasizes, "The efficiency and quality of your processing equipment can make or break your French fries business." This statement underlines the significance of selecting an appropriate machine that not only meets production needs but also enhances the overall quality of the end product.

In the competitive landscape of food service, having the right French fries processing machine can streamline operations, reduce labor costs, and ensure that your fries have the perfect texture and flavor. Factors such as production capacity, processing speed, and ease of maintenance are key considerations for businesses when choosing the appropriate equipment. By understanding these elements, operators can make informed decisions that align with their specific operational goals.

Ultimately, investing in a high-quality French fries processing machine is a step towards achieving success in the fast-paced food industry. As businesses strive for excellence in their offerings, the right equipment serves as a vital component in meeting customer expectations and maximizing profitability.

When selecting a French fries processing machine for your business, several critical factors must be taken into account to ensure you make the best choice for your operational needs. First and foremost, consider the machine's capacity. Depending on your business scale, you need to determine how much output you require daily. A machine with higher capacity may be necessary for larger operations, while smaller setups might benefit from a more compact model that can still deliver quality fries.

Another essential aspect is the technology and features of the processing machine. Look for equipment that offers advanced automation and efficiency to minimize labor costs and maximize production speed. Features such as adjustable slicing thickness, temperature control, and quick cleaning options can significantly enhance the overall functionality of the machine. Additionally, it's crucial to assess the machine's energy consumption, as a more energy-efficient model can lead to significant savings over time.

Lastly, consider the durability and maintenance requirements of the machine. Investing in a robust machine can withstand the demands of a busy kitchen while minimizing downtime for repairs. Researching user reviews and seeking advice from industry experts can provide insights into the longevity and reliability of the equipment, ensuring you choose a machine that supports your business's growth effectively.

When selecting a French fries processing machine for your business, it is essential to understand the various types available on the market. The fundamental categories include continuous fryers, batch fryers, and hybrid models. Continuous fryers operate on a nonstop basis, allowing for higher efficiency and volume, making them ideal for larger operations. According to a report by Grand View Research, the global market for industrial frying equipment is projected to reach USD 11.7 billion by 2027, significantly highlighting the demand for high-capacity processing solutions.

Batch fryers, on the other hand, are more suitable for smaller businesses or restaurants looking for flexibility and ease of use. They allow operators to cook a smaller amount of fries at a time, which can help in maintaining freshness and quality for smaller orders. The versatility of hybrid models combines features from both continuous and batch fryers, offering adaptability based on production needs. Industry experts from Research and Markets indicate that the shift towards automation and sophisticated processing technology is on the rise, as businesses aim to improve production efficiency while ensuring the highest quality standards.

Understanding the specifications and features of these processing machines is crucial for profitability and operational success. For instance, energy consumption, frying time, and the level of automation can significantly impact operational costs. As the demand for high-quality, consistent products grows, choosing the right type of processing machine serves not only to meet customer expectations but also to enhance the overall profitability of your operation.

When selecting a French fries processing machine for your business, it is crucial to focus on key features that can enhance efficiency and output quality. According to a report by Technavio, the global market for food processing equipment is projected to grow by over 5% annually, emphasizing the importance of investing in advanced processing technologies. First and foremost, consider the machine's capacity and throughput; the ability to process large volumes of potatoes quickly can significantly impact your production line's efficiency. Look for machines that can handle various potato sizes and types, as this versatility can streamline your operations.

Another essential feature is the degree of automation the machine offers. Automated French fries processing machines can reduce labor costs and minimize human error, leading to more consistent product quality. Data from Mordor Intelligence suggests that automation in food processing can increase productivity by up to 20%. Additionally, energy efficiency is increasingly vital; machines with lower energy consumption can significantly affect operational costs over time. Selecting a model equipped with advanced energy-saving technology will not only be cost-effective but also align your business with sustainability goals. Furthermore, ensure the machine is easy to clean and maintain, as this will reduce downtime and promote a safe working environment.

When it comes to choosing between manual and automatic French fries processing machines, the decision largely depends on the scale and specific needs of your business. A report from the Food Processing Industry Association estimates that businesses using automatic machines can increase efficiency by up to 50%, significantly reducing labor costs and processing time. Automatic machines also offer consistent results, ensuring that each batch of fries meets quality standards without the variability that can come from manual processing.

However, manual machines may still have a place, especially for smaller operations or those focusing on artisan-style food offerings. A comparative analysis shows that while manual machines are generally more affordable and allow for greater control over the cooking process, they require significantly more labor and time, potentially limiting production capacity. For establishments that prioritize customization and personal touch, manual machines could still provide a competitive edge.

Tips: When selecting a processing machine, consider your production volume and the skill level of your staff. If your operation is expanding, investing in an automatic machine may save costs in the long run despite the initial higher investment. For businesses that cater to niche markets, maintaining a manual process might enhance the artisanal aspect that attracts customers. Always evaluate your workflow and customer preferences to find the option that best suits your operational goals.

| Features | Manual French Fries Machine | Automatic French Fries Machine |

|---|---|---|

| Production Capacity (kg/hr) | 50 | 200 |

| Labor Requirement | 3-4 workers | 1-2 workers |

| Energy Consumption (kW) | 2 | 5 |

| Initial Cost ($) | 1500 | 8000 |

| Maintenance Requirement | High | Low |

| Ease of Use | Moderate | Easy |

| Space Requirement (sq m) | 10 | 25 |

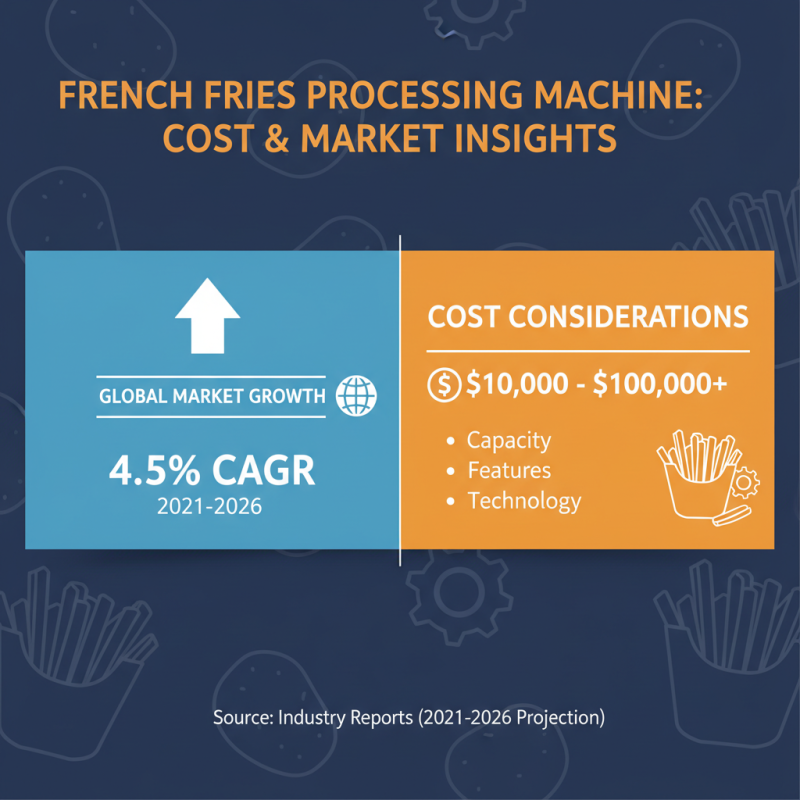

When selecting the best French fries processing machine for your business, understanding cost considerations and budgeting is crucial. According to industry reports, the global French fries market is projected to grow at a CAGR of 4.5% from 2021 to 2026, indicating a robust demand for efficient processing machinery. However, the high capital required for top-tier machines can deter some businesses. Price points for these machines can vary significantly, often ranging from $10,000 to over $100,000 depending on capacity, features, and technology.

When budgeting, it's essential to account for not just the purchase price, but also ongoing maintenance costs and energy consumption. A processing machine that may seem economical upfront could lead to higher operational expenses if it's not energy-efficient. For example, investing in modern machines that utilize advanced technologies can significantly reduce energy costs; studies indicate that upgrades can yield savings of up to 30% on electricity.

**Tips:** Always factor in the total cost of ownership, not just the initial expenditure. Look for machines that offer flexibility to handle various potato types and size, as this can increase your product range without requiring additional equipment. Additionally, consider leasing options as an alternative to purchasing, which can help manage cash flow while still allowing for high-quality production capabilities. Aim to research and compare features that will align with your production goals and financial constraints.