In the world of culinary equipment, the Steel French Fry Cutter stands out as an essential tool for both home cooks and professional chefs alike. According to a recent industry report by the Culinary Equipment Research Institute, the demand for high-quality fry cutters has seen a significant increase of 25% over the past five years, driven by the growing popularity of homemade and artisanal fries. The consistency and precision that a Steel French Fry Cutter can provide are invaluable, ensuring that each fry is cut to perfection, maximizing texture and flavor.

Chef Mark Thompson, a renowned expert in kitchen equipment, emphasizes the importance of selecting the right cutter: "A quality Steel French Fry Cutter not only enhances the aesthetic appeal of the dish but also contributes to the overall dining experience." With the right tool, restaurants can improve their operational efficiency and reduce food waste, all while delivering a superior product to customers. As more chefs recognize the importance of quality prep tools, the Steel French Fry Cutter is poised to become a staple in kitchens everywhere, elevating the art of fry making to new heights.

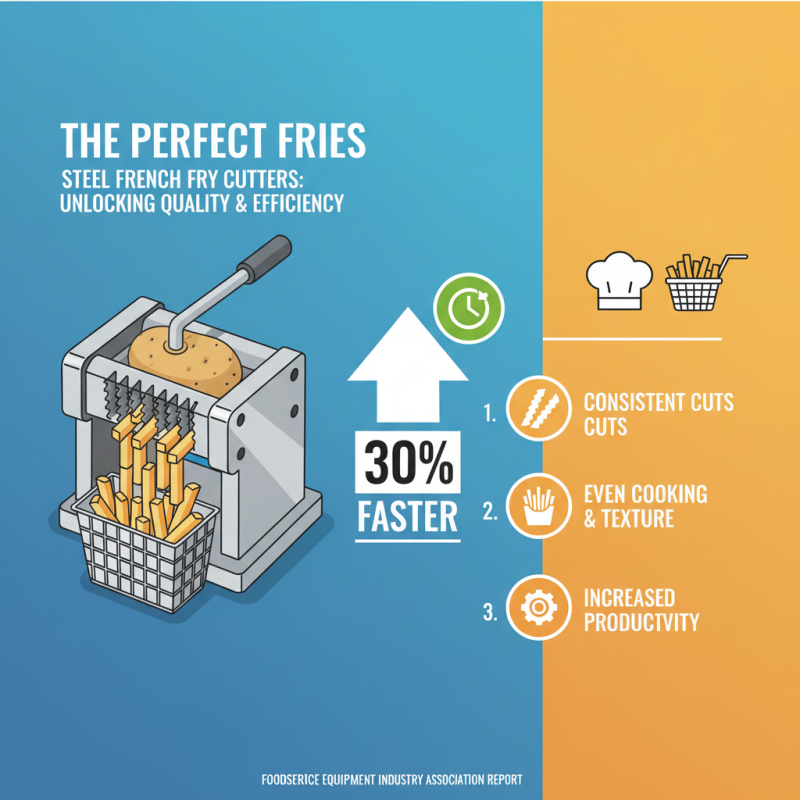

When it comes to achieving the perfect fries, the quality of the French fry cutter is a crucial factor that is often underestimated. Steel French fry cutters are particularly valued for their durability and efficiency in producing consistent cuts, which are essential for even cooking and optimal texture. According to a report from the Foodservice Equipment Industry Association, high-quality steel cutters can significantly reduce processing time by up to 30%, allowing for an increase in productivity during peak hours. This efficiency not only streamlines the workflow in commercial kitchens but also enhances the overall dining experience for customers.

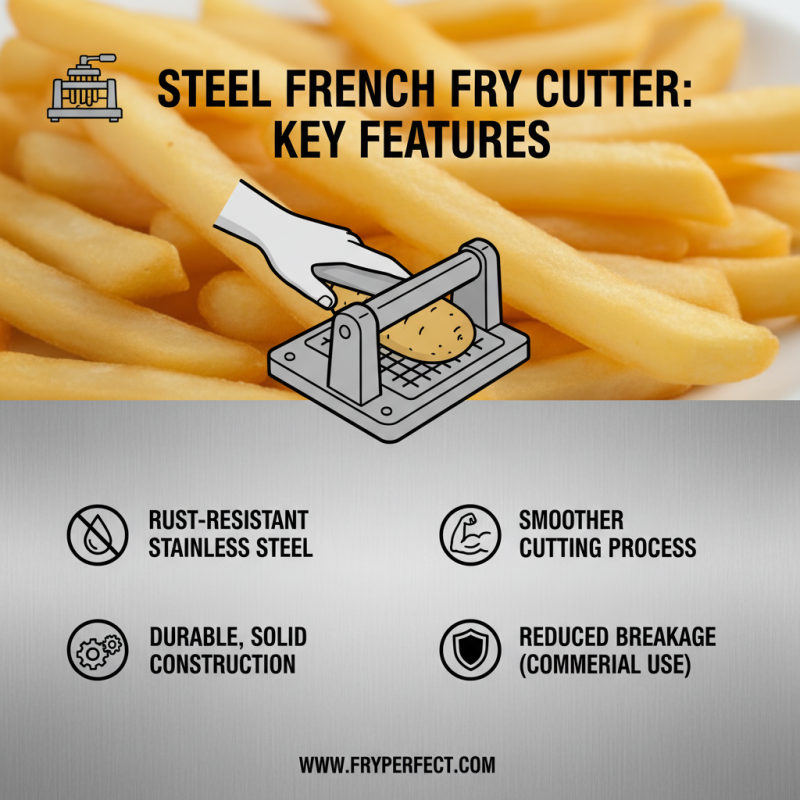

Moreover, the grade of steel used in these cutters plays a pivotal role in their performance and longevity. Stainless steel, in particular, is known for its resistance to corrosion and robust construction, ensuring that the cutter maintains sharpness over time. The National Sanitation Foundation emphasizes the importance of hygiene in food preparation tools; investing in high-quality materials can minimize the risk of bacteria accumulation, thereby contributing to food safety. When selecting a steel French fry cutter, it is essential to consider not just the initial cost, but also the long-term value derived from durability and performance, which can lead to reduced replacement frequency and lower operational costs.

When selecting the best steel French fry cutter, it’s essential to consider several key features that can significantly enhance your frying experience. First and foremost, the quality of the steel used in the cutter is paramount. A durable, rust-resistant stainless steel will ensure longevity and a smoother cutting process. Look for models that boast solid construction, as this will reduce the risk of breakage during heavy use, especially in a commercial setting.

Another vital feature is the ease of operation. A French fry cutter should ideally come with a comfortable handle that allows for a good grip, facilitating smooth and efficient cutting motions. Additionally, consider the size of the cutting blades. Most fry cutters come with multiple blade sizes, enabling you to create fries that suit your preference, whether they are thick-cut or shoestring.

Tips: When using your steel French fry cutter, it can be beneficial to soak your potatoes in cold water for at least 30 minutes before cutting. This helps in reducing the starch content, leading to crispier fries. Regular maintenance, such as cleaning and oiling the blades, will ensure your cutter remains in optimal condition and extends its lifespan.

When selecting a steel French fry cutter, understanding the types of steel used can significantly impact the durability and performance of the product. There are primarily two types of steel used in fry cutters: stainless steel and carbon steel. Stainless steel is known for its corrosion resistance and ease of maintenance, making it a popular choice for kitchen equipment. According to industry data, stainless steel can exhibit a lifespan that is 3 to 5 times longer than that of carbon steel when properly cared for. This is crucial in a high-volume setting where fry cutters are used frequently.

On the other hand, carbon steel is often favored for its exceptional sharpness and responsiveness, which can lead to better-cut fries. However, it requires more maintenance to prevent rust and corrosion. Reports indicate that carbon steel blades, when properly maintained, can provide an excellent balance between sharpness and durability, making them a viable option for those who prioritize cutting efficiency. Both types of steel serve their purpose in the culinary world, but choosing the right one ultimately depends on the user's specific needs—whether they prioritize longevity and low maintenance or sharpness and cutting precision.

When selecting a steel French fry cutter, it’s crucial to assess the cutter size and blade configuration to achieve the desired fry thickness. A well-designed cutter will feature a variety of blade sizes, allowing you to create fries that cater to different tastes and preferences. For instance, thicker cuts will provide a hearty bite and are perfect for those who appreciate a more substantial fry, while thinner blades yield crispier fries that are ideal for dipping or snacking. Understanding these dimensions will enable you to customize your fry-making experience, ensuring consistent results every time.

In addition to size, the blade configuration plays a pivotal role in the texture and quality of the fries. Straight blades are commonly used for classic French fries, but crinkle-cut blades can add a unique aesthetic appeal and help with gripping sauces. Additionally, consider the material of the blades; stainless steel provides durability and resistance to corrosion, ensuring a long-lasting tool in your kitchen. Taking the time to evaluate both the size of the cutter and the type of blades will empower you to create perfectly cut fries that suit your culinary needs and delight your taste buds.

Maintaining your steel French fry cutter is essential for ensuring its longevity and optimal performance. Regular cleaning is the first step. After each use, disassemble the cutter and wash the parts with warm water and mild soap to remove any residual starch and grease. Avoid using abrasive cleaners, as they can scratch the steel surface and diminish its sharpness. Ensuring your cutter is thoroughly dried after cleaning will also prevent rust and corrosion, which are common issues with steel tools.

Additionally, lubrication is key to keeping the moving parts functioning smoothly. Use a food-safe lubricant on any hinges or joints to reduce friction and wear. This simple step not only prolongs the life of your cutter but also ensures that it operates at peak efficiency.

**Tips:** Store your French fry cutter in a dry place to avoid moisture buildup, which can lead to oxidation. Regularly inspect the blades for dullness; sharpening them as needed will enhance cutting performance and make the process quicker and more efficient. Lastly, keep an eye out for any loose screws or parts, tightening them as necessary to maintain structural integrity and safety during use.

| Feature | Description | Importance |

|---|---|---|

| Material | High-quality stainless steel for durability and resistance to rust. | Essential for long-lasting performance. |

| Blade Types | Different sizes for various cut styles (e.g., thick, thin). | Allows for customization for preference. |

| Ease of Use | Simple operation with minimal effort required. | Important for user satisfaction and efficiency. |

| Maintenance | Easy to clean and requires minimal upkeep. | Crucial for longevity and hygiene. |

| Safety Features | Includes safety grips and non-slip bases. | Prevents accidents during use. |

| Size & Storage | Compact design for easy storage in kitchens. | Space-saving and convenient for small kitchens. |