In the quest for culinary excellence, selecting the right tools is paramount, especially when it comes to preparing ingredients efficiently. Among the most innovative advancements in kitchen technology is the Automatic Steam Peeler, a game-changing device that offers both speed and precision in peeling fruits and vegetables. As we move towards 2025, understanding how to choose the best automatic steam peeler becomes increasingly important for both home cooks and professional chefs looking to enhance their food preparation processes.

This guide aims to provide insights into the key features and functionalities that define a high-quality Automatic Steam Peeler, ensuring maximum efficiency without compromising on the quality of the end product. From the ease of operation to the maintenance requirements and durability, the factors discussed will empower users to make informed decisions tailored to their specific culinary needs. Whether you are preparing for a bustling restaurant environment or a family gathering, selecting the right model can streamline your cooking efforts and elevate your dish presentation.

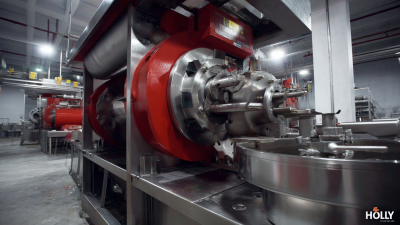

In commercial food processing settings, the efficiency of automatic steam peelers is influenced by several key factors. One primary consideration is the design and configuration of the peeler itself. According to a report by the Food Processing Research Institute, machines with advanced steam circulation technology can achieve up to 95% peeling efficiency, significantly reducing labor costs and time. Additionally, the ability to adjust steam pressure and temperature allows for optimal peeling of various fruits and vegetables, thereby minimizing waste and maximizing yield.

Another crucial factor is the machine's capacity and throughput. Research from the International Journal of Food Engineering indicates that systems capable of handling larger volumes—ranging from 1,500 to 5,000 kg per hour—are increasingly preferred in high-demand environments. This scalability not only meets the needs of large operations but also maximizes operational efficiency. Furthermore, maintenance requirements and ease of cleaning can greatly affect the uptime of these machines, with those designed for quick disassembly showing a 20% increase in operational efficiency according to a study by the Food Machinery Association. These elements are vital for businesses looking to enhance productivity while ensuring high-quality output.

| Peeler Model | Peeling Speed (kg/h) | Power (kW) | Steam Consumption (kg/h) | Efficiency Rating | Maintenance Frequency (months) | Weight (kg) |

|---|---|---|---|---|---|---|

| Model A | 100 | 15 | 50 | 90% | 6 | 200 |

| Model B | 120 | 18 | 60 | 92% | 8 | 220 |

| Model C | 110 | 16 | 55 | 88% | 7 | 205 |

| Model D | 130 | 20 | 65 | 95% | 5 | 230 |

When evaluating automatic steam peelers for quality performance, several key features should be considered to ensure maximum efficiency and output. One critical factor is the peeling rate, which is often measured in pounds per hour. According to a report by the Agricultural Marketing Resource Center, leading models can achieve peeling rates of up to 2,000 pounds per hour, significantly enhancing operational productivity for food processing industries. This speed not only reduces labor costs but also improves overall turnaround times in production.

Another essential feature to assess is the machine's energy consumption. The U.S. Department of Energy highlights that energy-efficient steam peelers can reduce energy use by up to 30% compared to older models. This efficiency not only lowers operating costs but also aligns with sustainability goals, making the equipment an attractive choice for environmentally-conscious businesses. Additionally, the construction quality—such as stainless steel components that resist corrosion and wear—directly impacts the longevity and reliability of the peeler, ensuring consistent performance over time. These characteristics are pivotal in selecting a steam peeler that meets both operational demands and quality standards in the food processing sector.

The peeling efficiency of automatic steam peelers is significantly influenced by steam pressure and temperature. According to the 2022 report by the Food Processing Technology Association, optimal steam conditions can enhance the peeling rate by up to 30%.

Higher steam pressure generally allows for quicker penetration into the fruit or vegetable's skin, resulting in a more effective peeling process. The ideal pressure range suggested for most automated systems is between 30 to 40 psi. This pressure range ensures that the steam effectively softens the skin without compromising the quality of the product underneath.

Temperature also plays a crucial role in the peeling efficiency of automated systems. Studies presented in the International Journal of Food Engineering indicate that maintaining a steam temperature around 85°C to 90°C significantly improves the peeling yield. At these temperatures, the cellular structure of the skin is affected, leading to easier skin removal while preserving the integrity of the flesh. Therefore, selecting an automatic steam peeler with adjustable pressure and temperature controls is key to maximizing the efficiency and quality of the peeling operation, ultimately affecting the overall productivity in food processing facilities.

When considering the investment in high-quality automatic steam peelers for food processing, conducting a cost-benefit analysis is crucial. While the initial purchase price may be higher than traditional peeling methods, the efficiency gained can lead to significant long-term savings. High-quality steam peelers reduce labor costs, minimize waste, and ensure quicker processing times, allowing businesses to handle larger volumes of products without sacrificing quality.

Tips for evaluating steam peelers include examining the machine's capacity and speed. Look for models that offer adjustable settings to optimize performance based on the type of produce being processed. Additionally, consider maintenance and warranty options, as reliable service can minimize downtime and further enhance cost-effectiveness.

It's also essential to assess the energy efficiency of automatic steam peelers. Machines that use less energy while delivering high performance can improve overall operational costs. A well-chosen peeler not only enhances productivity but also contributes to sustainable practices within the food production industry, making it a wise investment for processing companies aiming for efficiency and quality.

When it comes to operating automatic steam peelers, adhering to industry standards and best practices is crucial for maximizing efficiency and maintaining quality. One of the first steps is ensuring that the equipment is set up correctly, following the manufacturer’s guidelines to optimize steam pressure and temperature. This will not only enhance peeling performance but also reduce energy consumption, mirroring principles observed in other industries, such as the use of CO2-free process steam to drive down emissions.

Regular maintenance is another key practice that can significantly impact the lifespan of the steam peeler and the quality of the final product. This includes routine checks of steam lines and valves, along with cleanliness assessments to prevent contamination risks, similar to how industries are addressing challenges like phytophthora infestations in nurseries. Finally, training operators on the best practices for monitoring and adjusting the technology can help in reducing downtime and increasing production yield, ensuring that the operation remains both efficient and consistent in quality.