As the snack food industry continues to thrive, projected to reach a value of over $600 billion by 2025, the demand for high-quality processing equipment becomes increasingly essential. Among various production technologies, the Potato Chips Dryer Machine stands out as a critical component for achieving optimal taste and texture while maintaining operational efficiency. According to a recent market analysis by Grand View Research, the global potato chips market is expected to grow at a CAGR of 4.0% from 2021 to 2028, emphasizing the need for manufacturers to invest in effective dehydration technology to enhance product quality and extend shelf life.

Choosing the right Potato Chips Dryer Machine not only improves product consistency but also helps businesses stay competitive in a rapidly evolving market landscape. In this blog, we will explore key considerations for selecting the best dryer machine, delve into industry case studies, and uncover essential reasons that highlight the transformation of snack production processes.

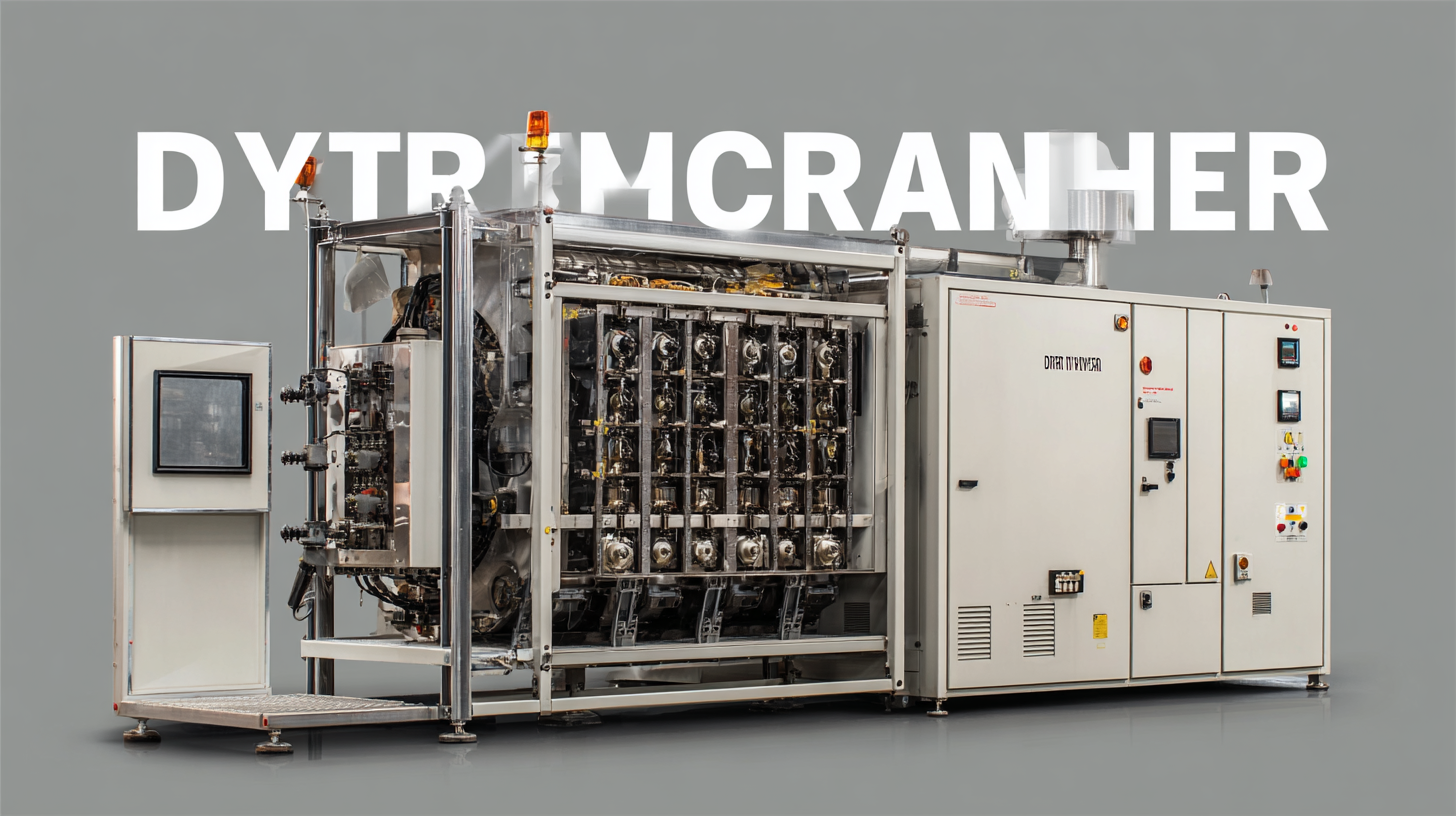

Emerging technologies in snack production are reshaping the landscape of potato chips drying, making it more efficient and environmentally friendly. Innovative machines now incorporate advanced heat pump technology, which significantly reduces energy consumption. This allows manufacturers to maintain the ideal temperature for drying without compromising the quality of the chips. As businesses look to upgrade their production lines, understanding these emerging technologies is crucial for staying competitive in a crowded market.

When selecting a potato chips dryer machine, consider the size and capacity that best fits your production needs. Tips for choosing the right machine include evaluating the energy efficiency rating, as this can lead to substantial savings over time. Additionally, look for drying machines equipped with smart technology that enables real-time monitoring and adjustments, ensuring consistent product quality and output.

Furthermore, investing in a dryer that uses gentle drying techniques can preserve the natural flavors and nutrients of your chips. It's advisable to conduct thorough research and possibly arrange demonstrations of different machines to see firsthand their performance. Collaborating with suppliers who offer robust support and training can also enhance your operational efficiency as you incorporate new drying technologies into your production process.

When selecting a potato chips dryer machine for your snack production business, certain key features can significantly impact efficiency and product quality. First and foremost, consider the drying technology employed by the machine. Hot air circulation and infrared drying are two popular methods; both ensure even moisture removal while preserving the crispness of the chips. A machine with adjustable temperature settings allows for optimal drying depending on the thickness of the chips, which is crucial for consistent quality.

Another essential feature to look for is energy efficiency. Since drying operations can consume a considerable amount of energy, selecting a machine with high thermal efficiency can reduce operational costs and environmental impact. Additionally, production capacity is vital—choose a machine that meets your business’s output demands without compromising on quality.

Finally, ease of cleaning and maintenance should be considered. A design that facilitates quick disassembly can help prevent cross-contamination and ensure your production line meets health and safety regulations. Prioritizing these features can lead to better production outcomes and ultimately enhance your brand’s reputation in the competitive snack market.

When selecting a potato chips dryer machine, evaluating energy efficiency and cost-effectiveness should be at the forefront of your decision-making process. Energy-efficient machines not only reduce operational costs but also contribute to a more sustainable production environment. With the rising costs of energy, investing in technology that minimizes energy consumption can significantly improve your bottom line. Look for dryers that utilize advanced heating technologies, such as infrared or hot air circulation systems, which can enhance drying efficiency without compromising the quality of the chips.

Moreover, consider the long-term savings that come with a cost-effective dryer. While the initial investment might be higher, machines that are built for durability and efficiency often have lower maintenance costs and longer lifespans. Analyze the total cost of ownership rather than just the purchase price. This includes energy consumption, maintenance requirements, and potential downtime. By focusing on these aspects, businesses can ensure that their choice of potato chips dryer not only meets their production needs but also aligns with financial goals in a competitive market.

| Dryer Machine Model | Energy Consumption (kWh) | Production Capacity (kg/hr) | Cost (USD) | Efficiency Rating (%) |

|---|---|---|---|---|

| Model A | 12 | 300 | 15,000 | 85 |

| Model B | 10 | 250 | 12,000 | 90 |

| Model C | 15 | 350 | 20,000 | 80 |

| Model D | 8 | 200 | 10,000 | 95 |

When selecting the right supplier for potato chips dryer machines, particularly from Chinese manufacturers, businesses must consider various factors that influence quality and efficiency. According to a report by Freedonia Group, the demand for snack processing equipment is projected to grow at a CAGR of 4.3% through 2025. This underscores the importance of choosing suppliers that not only offer competitive pricing but also advanced technology in dryer machines that enhance product quality.

Chinese manufacturers have increasingly distinguished themselves on the global stage by implementing stringent quality control practices and adopting cutting-edge technologies. Industry data suggests that over 30% of global snack production equipment is sourced from China, primarily due to its robust manufacturing capabilities and a network of suppliers that cater to varied business needs. When evaluating potential suppliers, businesses should prioritize manufacturers with ISO certifications and positive client testimonials to ensure reliability and high performance in their drying solutions.

As the snack industry evolves, sustainability and innovation emerge as pivotal trends shaping its future. The global potato chips market is currently experiencing a surge in gourmet flavors and eco-friendly packaging, reflecting consumer demand for higher quality and more responsible products. According to industry reports, this market is projected to gain substantial traction, driven by consumers' appetite for unique taste experiences coupled with sustainable practices.

Moreover, the protein snacks market, valued at $46.49 billion in 2023, is expected to grow significantly, reaching $100.56 billion by 2032. This indicates a robust shift towards health-focused snacking, where innovation plays a crucial role in meeting the dietary preferences of consumers. Events like ISM 2025, where Cologne will host global leaders in the sweets and snacks sector from February 2–5, highlight the industry's commitment to pioneering developments that resonate with evolving consumer expectations. The future of snack production will undoubtedly hinge on integrating sustainability with inventive approaches, positioning businesses to thrive in a competitive market landscape.