In the evolving landscape of food processing technology, the Boiled Potato Peeler Machine has emerged as a pivotal tool for enhancing efficiency in commercial kitchens and food production facilities. According to a report by Grand View Research, the global food processing equipment market is projected to reach USD 90 billion by 2025, driven by the increasing demand for automation and processing efficiency in food production. As restaurants and food manufacturers strive to reduce labor costs and improve productivity, investing in advanced peeling machines becomes essential.

The Boiled Potato Peeler Machine not only streamlines the peeling process but also ensures consistency and quality, which are critical factors in the competitive food industry. This technology leverages innovations in design and functionality to minimize waste, optimize peeling time, and preserve the nutritional value of potatoes. Industry data indicates that automating peeling processes can reduce labor requirements by up to 30%, allowing businesses to reallocate resources more effectively and focus on enhancing product offerings. As we explore the efficiency and benefits of the 2025 Top Boiled Potato Peeler Machine, it becomes clear that adopting such machinery is not just an operational upgrade but a strategic move towards achieving long-term growth and sustainability in the food sector.

The 2025 Boiled Potato Peeler Machine has made significant strides in both design and technology, leading the way in efficiency for commercial kitchens. This new generation of peeling machines integrates smart technology, allowing operators to adjust settings for different potato varieties easily. Enhanced blade designs ensure a more effective peeling process, reducing waste and maintaining the integrity of the potato's surface, which is crucial for cooking quality.

One of the standout innovations is the machine's automated self-cleaning feature, which minimizes downtime and enhances hygiene standards. By streamlining the cleaning process, users can focus more on food preparation rather than maintenance. Additionally, energy-efficient motors have been introduced, significantly lowering energy consumption while delivering consistent peak performance.

Tips for maximizing the use of your peeler include ensuring that potatoes are at the optimal size for the machine's specifications to prevent jams and enhance peeling efficiency. Regularly checking and maintaining the machine's blades can also ensure a smoother operation and prolong the lifespan of the equipment. Embracing these innovations not only boosts productivity but also contributes positively to the overall food preparation process.

The efficiency of boiled potato peeler machines is largely defined by two key metrics: speed and output. In today's fast-paced food industry, operators are increasingly under pressure to maximize production while minimizing labor costs. A well-designed potato peeling machine can significantly reduce the time required to prepare large quantities of potatoes, leading to greater overall efficiency. Machines equipped with advanced technology can peel potatoes in a matter of seconds, drastically outperforming manual methods and ensuring a steady workflow in processing plants.

Output is another critical factor to consider. Modern potato peelers are designed to handle large volumes, often capable of processing several hundred kilograms of potatoes per hour. This high throughput not only meets the demands of large-scale operations but also maintains quality control, ensuring that the potatoes are uniformly peeled without wasting excess product. By optimizing both speed and output, businesses can enhance their productivity, resulting in reduced operational costs and improved profit margins. Investing in efficient peeling machines thus becomes a strategic move to stay competitive in the market.

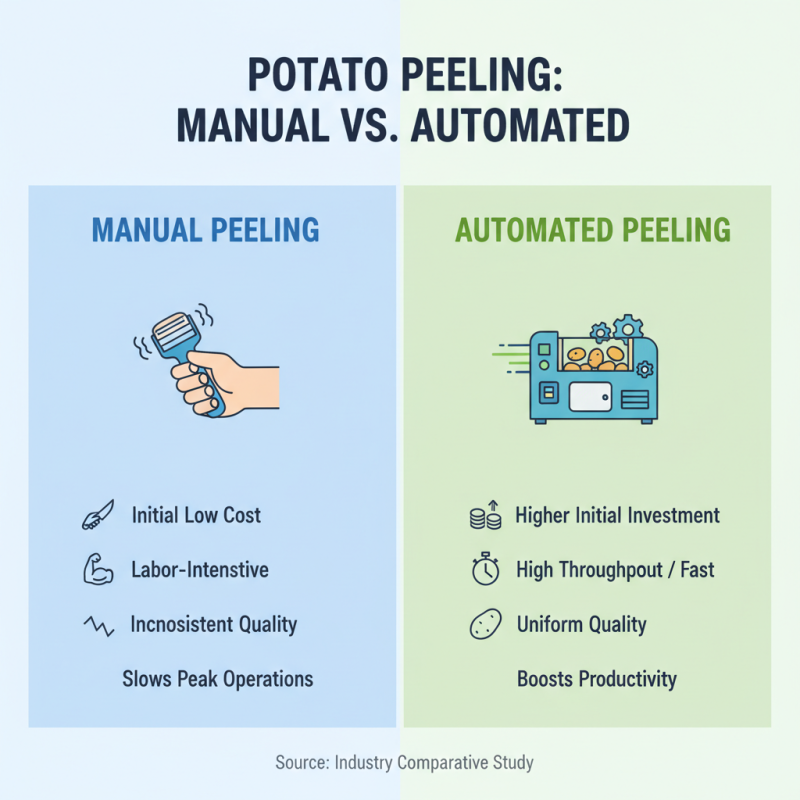

In commercial kitchens and food processing facilities, the efficiency of peeling potatoes can significantly impact productivity and labor costs. A comparative study of manual vs. automated peeling methods reveals notable differences. Manual peeling, typically performed by workers using knives or simple peelers, may be cost-effective initially. However, it is labor-intensive and can lead to variations in the quality of the peeled product. Workers can tire, and the peeling speed is limited, which may slow down overall operations, especially during peak hours.

On the other hand, automated peeling machines have revolutionized potato processing. These machines utilize advanced technology to peel large quantities of potatoes quickly and consistently. The efficiency achieved through automation can drastically reduce the time required for this task and minimize waste. Moreover, automated peelers can often be adjusted for different sizes and types of potatoes, ensuring a uniform result. This not only enhances product quality but also optimizes labor resources, allowing workers to focus on more complex tasks that require human oversight and expertise. As such, the adoption of automated peeling machines is becoming increasingly prevalent in the industry, driven by the need for enhanced efficiency and consistency in food preparation.

The advancement of technology in the food processing industry has led to the development of highly efficient boiled potato peeler machines, significantly impacting economic dynamics for food manufacturers. Automation in peeling processes not only enhances productivity but also contributes to substantial cost savings. A recent report from the Food Processing Machinery Association indicates that fully automated peeling systems can reduce labor costs by up to 30%, allowing companies to allocate resources more strategically.

In addition to labor reduction, these machines optimize resource utilization, minimizing waste and maximizing output. According to industry data, automated peeling systems can improve yield rates by 15-20%, translating into higher profits. Furthermore, the reduction in manual handling decreases the risk of workplace injuries and associated costs, further improving the financial outlook for businesses that adopt these technologies. As the market continues to embrace automation, the competitive edge it provides cannot be ignored, proving that investing in machines designed for efficiency is a crucial step towards sustainable growth in the food industry.

| Feature | Description | Economic Advantage |

|---|---|---|

| Automation | Reduces manual labor and increases output | 50% labor cost savings |

| Processing Speed | Peeling capacity of 500 kg/hr | Increased throughput leads to greater sales |

| Energy Efficiency | Uses 20% less energy than previous models | Lower utility bills |

| Maintenance Requirements | Minimal maintenance needed | Saving on repair costs |

| Quality of Peeling | Uniform peeling reduces waste | Higher product yield enhances profitability |

In the rapidly advancing food processing industry, the importance of safety regulations for peeler machines cannot be overstated. The design and manufacturing of boiled potato peeler machines must adhere to stringent industry standards that ensure the health and safety of workers. These regulations typically encompass various aspects, including electrical safety, mechanical safety, and hygiene requirements. Compliance with these standards not only protects personnel but also guarantees that the processed food meets quality control measures mandated by health authorities.

Moreover, manufacturers are increasingly focused on incorporating safety features into their peeling machines. This includes mechanisms such as emergency stop buttons, safety guards, and sensors to prevent accidents during operation. Regular maintenance checks and employee training programs play a crucial role in adhering to safety protocols, helping to mitigate risks associated with machine operation. Ultimately, complying with safety regulations not only fosters a secure working environment but also enhances the overall efficiency and reliability of the peeler machines used in food processing.